How is Jewelry Manufactured?

The current Indian market holds a variety of jewelry items. It is an ornament worn by people right from ancient times. Manufacturing quality products requires a lot of techniques and skilled craft workers. Even though the current craftsmen have perfected their techniques with the latest technology, the basic concept of jewelry manufacturing remains the same. The current metals commonly in use include gold, silver, Brazil, and platinum. People also use copper to provide unique collections. Each jewelry industry comprises micro-businesses, enterprises businesses, enterprises, and manufacturers. With jewelry manufacturing, the natural traditional designs can be taken as a microengineering technique that requires great accuracy. Initially, the makers use the metals to create chains and other designs that can be finished with the stones and polished to become the highest grade of collection. Understanding the manufacturing technique will make your purchase valuable and understandable. Perhaps people might also understand why the making charges are higher for certain pieces.

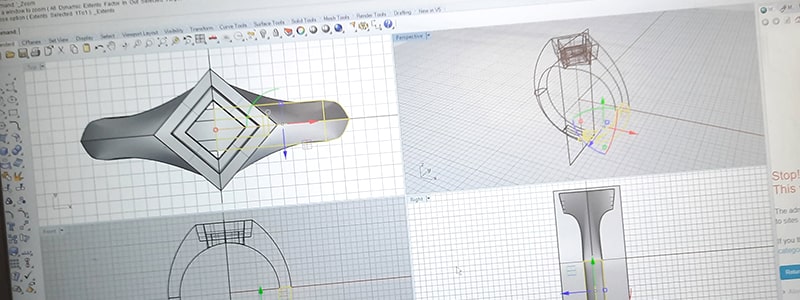

Designing

Any of the jewelry manufactured so far would have passed this stage. This is the foremost stage where the clients and designers work together to understand the designs they require. During this stage, the designers analyze the potential and pitfalls of the materials and how they will be suitable for the setting.

Cutting and Metal Formation

The next step in the jewelry-making process includes the cutting of metal into multiple small portions so that they can be designed and appropriately joined. The workers usually cut the metal with a better piercing saw and laser. Even though most people prefer using a piercing saw, the laser has proved effective, especially with automated manufacturing techniques. So the expert takes the original mental and divides it based on the weight requirement of the design and process. Forming is nothing but the idea used to shape the metal with the help of hammering, steak, bending, and sinking. The current technology has introduced multiple other formation processes, making it easier for the jewelry manufacturer. A formation is a primary tool that improves the hand pierced designs. Currently, any jewelry maker will prefer digital techniques over handcrafted techniques because of the precision, especially with gold and silver. The maker adds the other required metals with metals like gold and silver to ensure flexibility and formation.

Creating Piece

The manufacturing process can be pretty hectic based on the technique used by the designer. With digital technology, they can create the pre-designed mold to pour the melted metal. The designer usually creates these models with the help of digital machines. But they can also be prepared through handcrafted techniques for creating designs. We can make the Handcrafted collections through constant heating and alteration in the design. But remember, the handcrafted collections will have higher wattage when compared to the others.

Soldering

Soldering is the technique used to join the metals through excessive heating. In the soldering technique, the creator provides the final finish by combining multiple pieces. But this is not the final finish for the design. There is much more to make it valuable. The manufacturers use the gas torch, laser welding, and TIG welding for exclusive usage in many studios.

Casting

As mentioned above, in the manufacturing process, casting plays a major role. The Designers use them to fill the molten metal and alter it to a particular design. Even though it seems like a simple process, the reality is pretty complex and specialized. It permits multiple unit production at the same time. It makes it possible for the showroom to display many pieces of jewelry. The experts perform the carving process through hand and wax carving machines. Most shops get the cast from other jewelers and create the designs since it is cheap and best. But people who prefer uniqueness, like the DWS, will cast their molds and use them to create beautiful jewelry.

Stone Setting

The next step is setting the stone. If it is a gemstone-based design, the creators use multiple stone setting techniques to provide unique collections. Depending upon the design and the customers, the jewelry makers select their gemstone setting. The stones must last forever with an affirmed fixing, especially diamonds and other valuable gemstones. They will lose the jewel's value when the gemstone setting is poor. The quality of most gemstones lies within their position. It is necessary to create an appropriate environment.

Polishing

After the process, they subject the product to continuous polishing to improve the Shine and make it perfect for regular wear. With no polishing, it is impossible to get the bling in jewelry. One cannot determine the value of a product by the amount of gold present in them. It also focuses on its design and final outlook.

Die Striking Technique

Along with the traditional jewelry making technique, designers use this dye-striking technology to create thin gold and other jewelry items. The designers take a sheet of metal, and the design is made by punching the thin sheets into a shape. The designers will place a metal with the imprint on the machine, then start punching into the sheet. They use this technique to create multiple standing items, and it is like a hole punch, except it provides an impression. We mainly used them to design pendants and earrings.

Why Choose DWS?

With DWS, the options are higher when compared to the other stores. With exclusive customization options, we have our very own jewelry manufacturing unit. We provide many manufacturing processes, including machine-made and handcraft techniques.

From casting to polishing, we perform each activity with the help of an expert employee. The employees dedicate themselves to our purpose. Other collections or not just restricted to modern jewelry. We offer designs suitable for brides and other people who need a beautiful product to showcase their beauty. For more details, visit our showroom in Jaipur. They do not restrict our collections to gold, but we offer collections in multiple metals. Our gemstones are well tested for quality and certified to support the quality. People can also visit us on our website and chat with our designers to complete their customized collections.

I find it fascinating how traditional jewelry-making techniques have been combined with modern technology.

ReplyDelete